Decommissioning

The North Sea Transition Authority (NSTA) estimates that £24bn will be spent on decommissioning offshore infrastructure between 2023 and 2032 – a £3bn increase from previous forecasts. As offshore infrastructure reaches the end of its operational life, developers and governments face mounting financial and environmental pressures to manage decommissioning in a sustainable, cost-effective way.

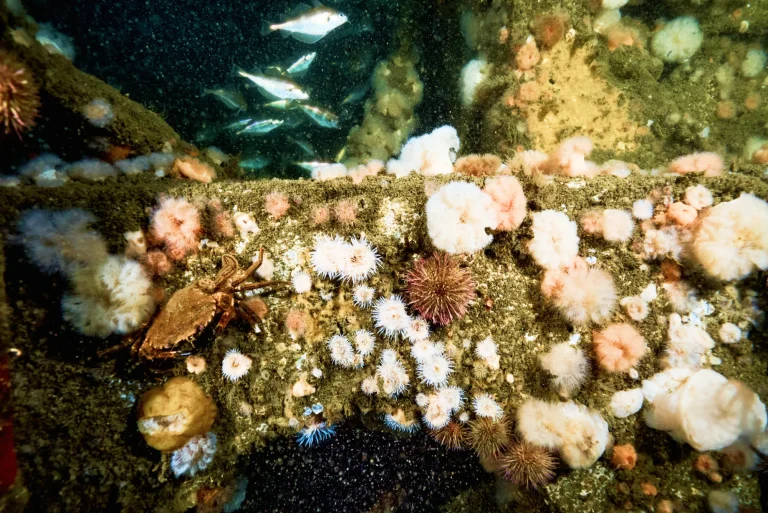

Traditional decommissioning involves removing, dismantling, and disposing of offshore platforms, subsea structures, and pipelines – a complex, high-risk, and expensive process. After decades in the ocean, these structures often serve as thriving marine habitats, and full removal can cause significant disruption to surrounding ecosystems. With decommissioning costs partially offset by government tax reliefs, reducing these expenses directly benefits both developers and taxpayers.

Our goal is to better this process with our unique suite of products that are much longer lasting, designed for scale and multi-application, and contain no plastic and reduce carbon.

Addressing the Challenges of Offshore Decommissioning

Cost-Effective, Environmentally Responsible Solutions

Looking for help and advice on decommissioning?

Arrange a call

Start-to-finish Turn-Key Process

Working closely with our clients, we’re able to assist with each stage of the project, ensuring it’s carried out to the highest standards possible. Rest assured in knowing it will be driven by innovative technology, scientific expertise, and a commitment to sustainability and increasing biodiversity.

Backed by multiple industry awards and accreditations such as B-Corp, ISO 9001, 14001 & 45001 – to ensure this highest standard of delivery.

Book your no-obligation consultation today and find out how we can transform your project.

Consultation

The first phase is to talk things through and gauge your situation, and which of our products is the best solution for it. We would establish the scale of the requirements, location, application and anything else bespoke that may be required for your project.

Design

We then work closely with our in-house science and engineering teams to create tailored designs based on the deployment location and project goals.

This enables us to deliver a nature-inclusive design to reflect the local marine environment and target the growth of specific species.

Manufacturing

At this stage, we ensure all our products are built as close to the deployment location as possible, using local labour and raw materials where possible.

Further carbon reductions and cost savings occur through manufacturing “in country” and utilising a combination of our globally transportable mobile production plant and using local raw material suppliers.

Permits & Licensing

We will assist with bid writing right from the tender stage & compliance through to conditions, obtaining permits and licensing for deposits onto the seabed with government bodies.

We can even take care of stakeholder management with fisheries, government, community groups and governing boards.

Transport & Logistics

Local deployment at your project location ensures that the entire process supports the local economy and follows industry-standard procedures with industry-standard hardware and vessels for added efficiency. We also have our own portfolio of deployment equipment that has been designed by our team from over 30 years of industry experience

Monitoring

Pre & post-deployment, we can deploy multiple monitoring techniques such as eDNA or ROV’s to assess the effectiveness of our subsea protection and artificial reef products. This allows us to track progress, monitor the development of marine life, compared to the baseline and fine tune our solutions for optimal results.

Our experts here to help

Support & Guidance

- Expert consultation

- Personalised advice for your specific project

- No obligation, just an open conversation

Our Products

Our Product Range

Explore More services

Other services